CXH18 mining intrinsic safety programmable display operation

The CXH18 intrinsically safe programmable display operation box is suitable for mines with gas and coal dust explosion hazards.

Product Overview

The CXH18 mining intrinsic safety programmable display operation box adopts an intrinsic safety design and is suitable for underground mines with gas and coal dust explosion hazards. The control box can achieve on-site control, data acquisition, transmission, and alarm functions. The operation box is equipped with a 10.1-inch color intrinsic safety touch screen, which displays clearly and is easy to operate; Each operation box has an independent power supply to ensure safe maintenance; Equipped with an Ethernet data upload interface, it can achieve data transmission with other substations and main stations. The internal controller integrates a dual controller mode of PLC controller and Mine Hong controller for users to choose from.

Safe and reliable

Mining intrinsic safety design, explosion-proof display screen, suitable for harsh coal mine underground environments that are flammable and explosive; Each operation box has an independent power supply to ensure safety during maintenance.

Powerful

The control box can achieve on-site control, data acquisition, transmission, and alarm functions. It has various operation buttons such as knobs, buttons, multi gear selection switches, and emergency stop operation switches.

Multi channel input/output

Equipped with 8 passive contact signal inputs/outputs; Equipped with 12 channels of 4mA to 20mA current type analog signal inputs; It has 9 PT100 analog signal inputs.

Working Principle

Intrinsic safety power supply

The KXJ-660 control box outputs an inherently safe power supply, providing stable power to the CXH18 operation box. Through circuit energy limiting design, it ensures safe operation in flammable and explosive environments.

Button signal acquisition and transmission

-

The output signal of the operation box button is processed by an intrinsic safety circuit and transmitted to the programmable control box through an Ethernet interface, achieving real-time and reliable transmission of control instructions.

Real time display of data

After processing signals, the programmable control box feeds back on-site data (such as equipment status and parameters) to the operation box display screen through Ethernet, achieving real-time visual monitoring and operation feedback.

Structural Composition

box

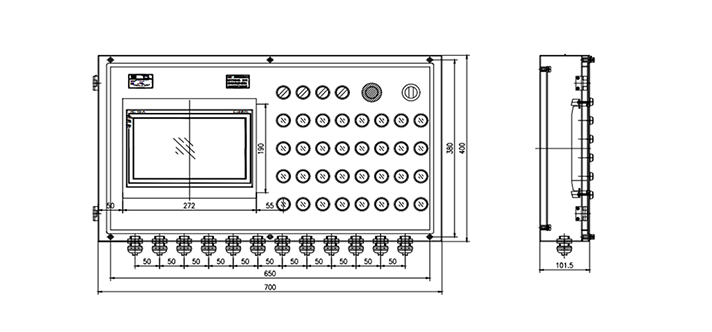

Inherent safety design; Compact structure, small volume, and light weight; Dimensions: 700 × 400 × 111 (mm); Quality: 20kg.

LCD screen display device

10.1-inch color LCD display screen, touchable operation; The touch screen is designed with intrinsic safety and explosion-proof safety.

control button

32 button signals, 4 three gear selection button signals; 1-channel eight speed knob signal; 1 emergency stop button signal; Complete operations such as starting and stopping on-site equipment; The button is wear-resistant and durable, and the operation is flexible without jamming.

Data interface module

1 Ethernet electrical signal; 2 Ethernet optical interfaces; 1 RS485 signal; 1-channel CAN signal interface (Mine Hong controller). High transmission efficiency and stable transmission.

Project Case

Guonuo weighing equipment has been successfully applied to multiple domestic and foreign enterprises and has gained widespread recognition

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Scale Project

Based on the site conditions, an ICS-17A belt scale frame was configured, which is a four-idler double-lever type frame with high stability. The sensors are built-in and less prone to damage, effectively mitigating the impact of belt misalig

Fengning Jianyu Iron Mine ICS-17A Belt Weigher Project

The ICS-17A belt weigher adopts a four-idler double-lever scale frame, ensuring high stability and good resistance to eccentric loading.

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Weigher Project

The measurement accuracy of the explosion-proof belt weigher met production requirements, and data could be viewed remotely. Production reports facilitated statistical analysis and management.

Hubei Jingshan Chutian Barium Salt Feeder Project

The feeder's metering and feeding accuracy fully met production requirements and remained stable during prolonged continuous production.

Production Process

Guonuo Technology adopts internationally leading production processes and equipment to ensure stable and reliable quality

Intrinsically safe explosion-proof type

Adopting a mining intrinsic safety design, the explosion-proof display screen has passed impact resistance certification, and an independent power module supplies power to each operation box to ensure safety during maintenance in gas and coal dust environments.

Multi functional control integration

Integrated knobs, buttons, multi gear selection switches, and emergency stop operations, supporting local control, data acquisition, transmission, and alarm, and implementing complex control logic through PLC logic processing.

Multi signal interface expansion

Equipped with 8 passive contact inputs/outputs, 12 4-20mA analog inputs, and 9 PT100 temperature inputs, supporting multiple types of sensor access to meet complex monitoring requirements.

Intelligent network interaction

Provides Ethernet optical/electrical ports, RS485 and CAN interfaces, supporting multi protocol data transmission; The 10.1-inch LCD touch screen enables human-computer interaction, with intuitive and convenient parameter settings and status monitoring.

Recommended similar products

Explore other high-quality products from Guonuo Technology to meet your diverse needs

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Scale Project

Based on the site conditions, an ICS-17A belt scale frame was configured, which is a four-idler double-lever type frame with high stability. The sensors are built-in and less prone to damage, effectively mitigating the impact of belt misalig

What are the characteristics of automatic quantitative feeders that align with industrial mass production?

With core advantages such as high precision, high automation, and easy maintenance, automatic quantitative feeders have become indispensable key equipment in modern industrial mass production.

Technical Advantages of Guonuo Technology's Mine Explosion-Proof Electronic Belt Scale

Guonuo Technology, as a manufacturer of mine explosion-proof electrical equipment and industrial weighing and metering devices, leverages its extensive experience, technical prowess, and meticulous attention to detail to introduce a mine exp

Sustainable Development Commitment

Guonuo Technology integrates the concept of sustainable development into the weighing industry, committed to balancing resource development and environmental protection

Environmental protection

- Invest 200 million yuan to build a mine water treatment system, with a water recycling utilization rate of 95%

- Adopting a closed coal transportation system to reduce dust emissions by over 80%

- Implementing the mine land reclamation plan, 1200 acres of vegetation have been restored

social responsibility

- Provide over 500 job opportunities for the surrounding communities of the mining area

- Invest in the construction of 3 Hope Primary Schools and 2 Community Medical Centers

- Annual investment of 10 million yuan for community development and poverty alleviation projects

Future goals

- Reduce carbon emissions intensity in production processes by 20% by 2030

- Invest 500 million yuan to develop low-carbon coal washing technology and clean utilization technology

- Realize 100% land reclamation and ecological restoration of mines by 2030

consulting product

Whether you need to know product details, obtain quotes, or explore long-term cooperation, our professional team will provide you with high-quality service.