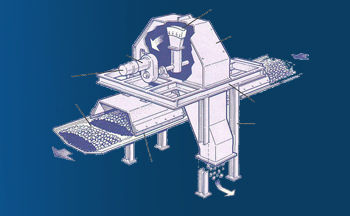

Belt head sampling machine

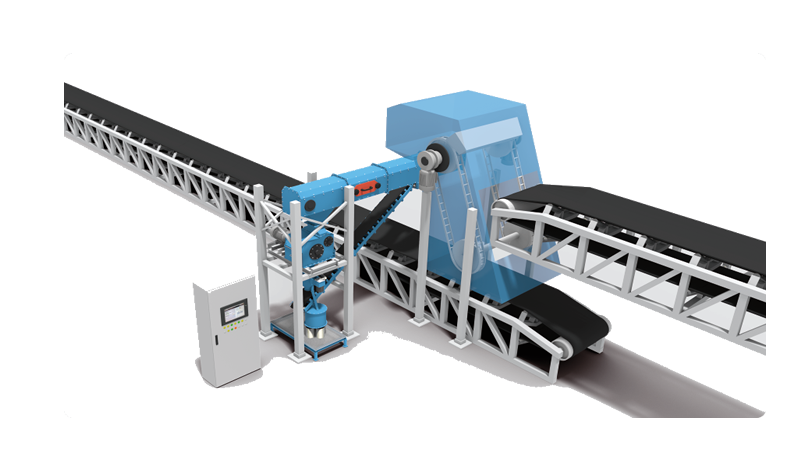

The automatic sampling equipment for belt head is a specialized equipment for mechanical automation sampling of bulk materials such as coal, furnace coal, and mineral products on the belt. It is widely used in industries such as power, steel

Product Overview

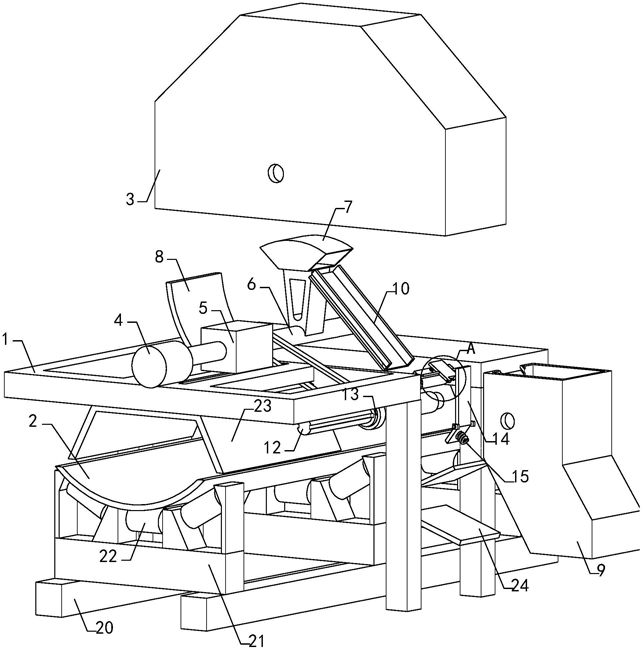

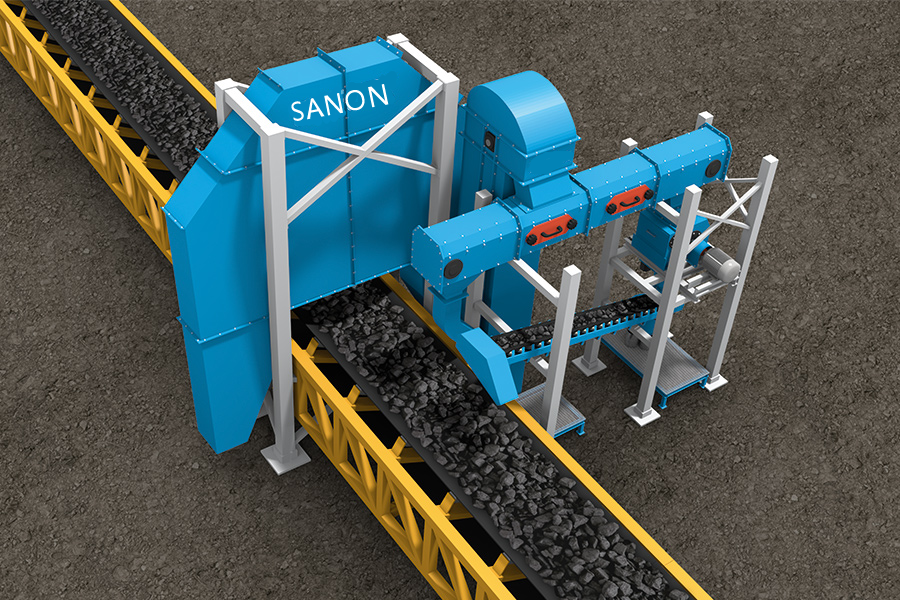

The belt head sampling machine is installed at the head of the belt conveyor. When the material conveyed by the belt falls along the material flow trajectory, the sampling machine passes through and samples the discharge mold section to obtain the sample. The collected materials are sent to the primary feeder, which evenly feeds the materials into the primary crusher. They are then divided and sent to the secondary crusher, and finally to the sample collector. The remaining coal is returned to the system through the return equipment.

Non destructive dynamic sampling

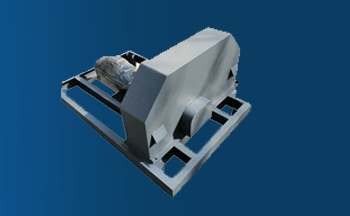

The sampling head is located at the head of the belt conveyor, accurately cutting into the natural downward trajectory of the material for full section scraping. The cleverness lies in the non-contact operation of the entire sampling process with the belt, which completely avoids the wear of the belt while obtaining a complete sample, ensuring the smooth and reliable long-term operation of the equipment from the root.

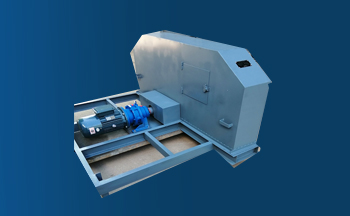

Intelligent fragmentation

The samples are uniformly fed into the crushing system through a primary feeder. The unique wet coal crushing technology can strictly control the particle size of the discharged material within a certain range, and with the automatic cleaning function, fundamentally solves the problem of blockage and sticking caused by high moisture and viscous materials, ensuring that the preparation process is always smooth and unobstructed.

unattended

The entire system operates fully automatically under the control of the upper computer and PLC, truly achieving unmanned sampling on site. At the same time, the system forms a fully enclosed purification process: the final sample is automatically collected, while the remaining material is automatically returned to the main belt by the bucket elevator. There is no dust or accumulated material on site, achieving the unity of efficiency and environmental protection.

Working Principle

Accurate sampling

The PLC controls the sampling device to start, and the sampling head rotates at a preset speed under the drive of the deceleration mechanism, completely cutting the material flow discharged from the head drum of the belt conveyor, ensuring the acquisition of unbiased sub samples and providing a reliable basis for subsequent processing.

sample preparation

-

The sub samples enter the primary belt conveyor through the chute, and are processed to the specified particle size by the crusher. Then, they are divided into retained samples and discarded materials by the classifier according to the program, achieving quantitative and standardized processing of the samples.

Control and closed-loop

The PLC system controls the sampling period, and the sampling head rotates to the preset angle to complete one sampling. The samples are collected in the storage tank, and the discarded materials are returned to the main belt through the bucket elevator, forming a closed loop. The system ensures real-time and representativeness of the sampling frequency and total amount by adjusting the sampling interval. AI-generated

Structural Composition

Project Case

Guonuo weighing equipment has been successfully applied to multiple domestic and foreign enterprises and has gained widespread recognition

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Scale Project

Based on the site conditions, an ICS-17A belt scale frame was configured, which is a four-idler double-lever type frame with high stability. The sensors are built-in and less prone to damage, effectively mitigating the impact of belt misalig

Fengning Jianyu Iron Mine ICS-17A Belt Weigher Project

The ICS-17A belt weigher adopts a four-idler double-lever scale frame, ensuring high stability and good resistance to eccentric loading.

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Weigher Project

The measurement accuracy of the explosion-proof belt weigher met production requirements, and data could be viewed remotely. Production reports facilitated statistical analysis and management.

Hubei Jingshan Chutian Barium Salt Feeder Project

The feeder's metering and feeding accuracy fully met production requirements and remained stable during prolonged continuous production.

Production Process

Guonuo Technology adopts internationally leading production processes and equipment to ensure stable and reliable quality

Non contact sampling

The sampling bucket is located at the lower part of the belt drum, only in contact with the falling material and not touching the belt. It not only collects the complete cross-section, but also avoids wear on the belt, ensuring smooth and reliable operation.

Adaptive working conditions

PLC controls the sampling head to cut materials across the entire cross-section, unaffected by changes in material flow and characteristics, ensuring that sub samples truly reflect the entire batch of materials, with strong representativeness and reliable results.

unattended

The system operates fully automatically, integrating unique crushing and cleaning devices to effectively handle wet and sticky materials, prevent material blockage and adhesion, and achieve unmanned and smooth operation.

strong adaptability

The entire process from sampling to residual material processing is enclosed, and the discarded materials are transported back in a dust-free manner. There is no accumulation of material dust on site. Supports multiple control modes such as automatic, manual, and remote, with strong adaptability and convenient operation.

Recommended similar products

Explore other high-quality products from Guonuo Technology to meet your diverse needs

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Scale Project

Based on the site conditions, an ICS-17A belt scale frame was configured, which is a four-idler double-lever type frame with high stability. The sensors are built-in and less prone to damage, effectively mitigating the impact of belt misalig

What are the characteristics of automatic quantitative feeders that align with industrial mass production?

With core advantages such as high precision, high automation, and easy maintenance, automatic quantitative feeders have become indispensable key equipment in modern industrial mass production.

Technical Advantages of Guonuo Technology's Mine Explosion-Proof Electronic Belt Scale

Guonuo Technology, as a manufacturer of mine explosion-proof electrical equipment and industrial weighing and metering devices, leverages its extensive experience, technical prowess, and meticulous attention to detail to introduce a mine exp

Sustainable Development Commitment

Guonuo Technology integrates the concept of sustainable development into the weighing industry, committed to balancing resource development and environmental protection

Environmental protection

- Invest 200 million yuan to build a mine water treatment system, with a water recycling utilization rate of 95%

- Adopting a closed coal transportation system to reduce dust emissions by over 80%

- Implementing the mine land reclamation plan, 1200 acres of vegetation have been restored

social responsibility

- Provide over 500 job opportunities for the surrounding communities of the mining area

- Invest in the construction of 3 Hope Primary Schools and 2 Community Medical Centers

- Annual investment of 10 million yuan for community development and poverty alleviation projects

Future goals

- Reduce carbon emissions intensity in production processes by 20% by 2030

- Invest 500 million yuan to develop low-carbon coal washing technology and clean utilization technology

- Realize 100% land reclamation and ecological restoration of mines by 2030

consulting product

Whether you need to know product details, obtain quotes, or explore long-term cooperation, our professional team will provide you with high-quality service.