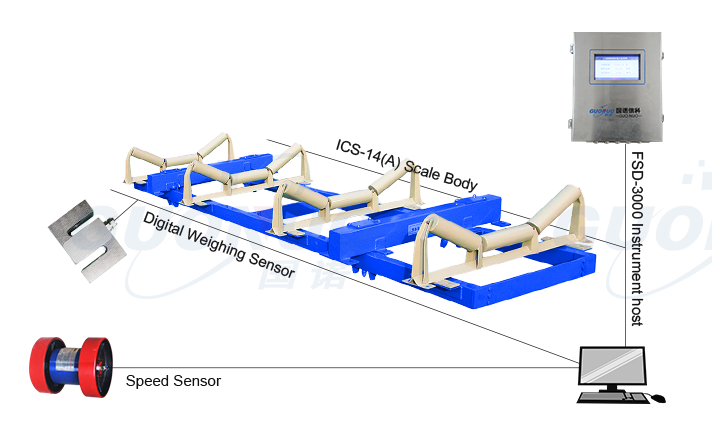

ICS-14A Electronic Belt Scale

The ICS-14A electronic belt scale is a high-precision, four-idler, fully suspended electronic belt scale

Product Overview

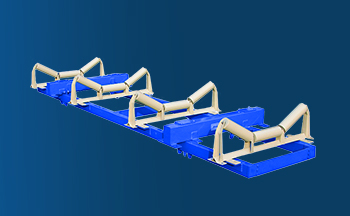

The ICS-14A electronic belt scale is a high-precision, four-roller, fully suspended electronic belt scale with four load cells. It features no ear shaft bearings or moving parts, resulting in lighter self-weight and minimal influence from its mechanical structure during weighing, achieving a maximum accuracy of 0.25%. Widely used in scenarios requiring trade settlement or high measurement accuracy, it meets the demands of trade settlement.

High precision

Four weighing sensors directly transmit force, and a four roller fully suspended scale frame eliminates errors caused by the fulcrum, with an accuracy of up to 0.25%.

Stable operation

No ear pivot and moving parts, lighter weight, basically unaffected by its own mechanical structure, rectangular steel structure, uniform force distribution.

Low maintenance

Carbon steel material does not wear out, rectangular steel structure, does not deform, requires minimal maintenance, and has low maintenance costs.

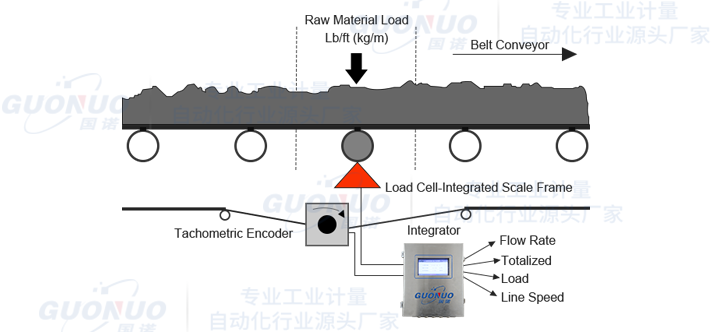

Working Principle

Generate signals

The weighing bridge is installed on the conveyor frame. When the material passes by, the measuring roller detects the weight of the material on the belt conveyor and acts on the weighing sensor through a lever, generating a voltage signal proportional to the belt load.

Speed calculation

-

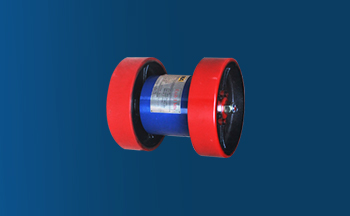

The speed sensor is directly connected to the large-diameter speed measuring drum, providing a series of pulses, each pulse representing a belt movement unit, and the frequency of the pulses is proportional to the belt speed.

Calculation result

The weighing instrument receives signals from the weighing sensor and speed sensor, integrates them to obtain an instantaneous flow rate value and an accumulated weight value, and displays them separately.

Structural Composition

Project Case

Guonuo weighing equipment has been successfully applied to multiple domestic and foreign enterprises and has gained widespread recognition

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Scale Project

Based on the site conditions, an ICS-17A belt scale frame was configured, which is a four-idler double-lever type frame with high stability. The sensors are built-in and less prone to damage, effectively mitigating the impact of belt misalig

Fengning Jianyu Iron Mine ICS-17A Belt Weigher Project

The ICS-17A belt weigher adopts a four-idler double-lever scale frame, ensuring high stability and good resistance to eccentric loading.

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Weigher Project

The measurement accuracy of the explosion-proof belt weigher met production requirements, and data could be viewed remotely. Production reports facilitated statistical analysis and management.

Hubei Jingshan Chutian Barium Salt Feeder Project

The feeder's metering and feeding accuracy fully met production requirements and remained stable during prolonged continuous production.

Production Process

Guonuo Technology adopts internationally leading production processes and equipment to ensure stable and reliable quality

carbon steel material

Rectangular steel structure, with uniform force distribution and greater stability. High quality carbon steel material, wear-resistant, maintenance free. Customize stainless steel material according to user needs.

Independently developed

Menu prompts, human-machine dialogue, and diverse operations. Intelligent analysis of operational status and optimization of processing. Fast A/D conversion rate, strong anti-interference ability, and flexible function expansion.

Well-known brand

Imported from the United States, with superior overall performance. Multiple protection functions to reduce problem errors. Can maintain stable operation in harsh environments.

Patent protection

Patent product, with Omron brand as the core component. Durable casing, suitable for outdoor installation. Double roller design structure detects roller speed. No need to adjust or replace carbon brushes, long service life.

Recommended similar products

Explore other high-quality products from Guonuo Technology to meet your diverse needs

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Scale Project

Based on the site conditions, an ICS-17A belt scale frame was configured, which is a four-idler double-lever type frame with high stability. The sensors are built-in and less prone to damage, effectively mitigating the impact of belt misalig

What are the characteristics of automatic quantitative feeders that align with industrial mass production?

With core advantages such as high precision, high automation, and easy maintenance, automatic quantitative feeders have become indispensable key equipment in modern industrial mass production.

Technical Advantages of Guonuo Technology's Mine Explosion-Proof Electronic Belt Scale

Guonuo Technology, as a manufacturer of mine explosion-proof electrical equipment and industrial weighing and metering devices, leverages its extensive experience, technical prowess, and meticulous attention to detail to introduce a mine exp

Sustainable Development Commitment

Guonuo Technology integrates the concept of sustainable development into the weighing industry, committed to balancing resource development and environmental protection

Environmental protection

- Invest 200 million yuan to build a mine water treatment system, with a water recycling utilization rate of 95%

- Adopting a closed coal transportation system to reduce dust emissions by over 80%

- Implementing the mine land reclamation plan, 1200 acres of vegetation have been restored

social responsibility

- Provide over 500 job opportunities for the surrounding communities of the mining area

- Invest in the construction of 3 Hope Primary Schools and 2 Community Medical Centers

- Annual investment of 10 million yuan for community development and poverty alleviation projects

Future goals

- Reduce carbon emissions intensity in production processes by 20% by 2030

- Invest 500 million yuan to develop low-carbon coal washing technology and clean utilization technology

- Realize 100% land reclamation and ecological restoration of mines by 2030

consulting product

Whether you need to know product details, obtain quotes, or explore long-term cooperation, our professional team will provide you with high-quality service.