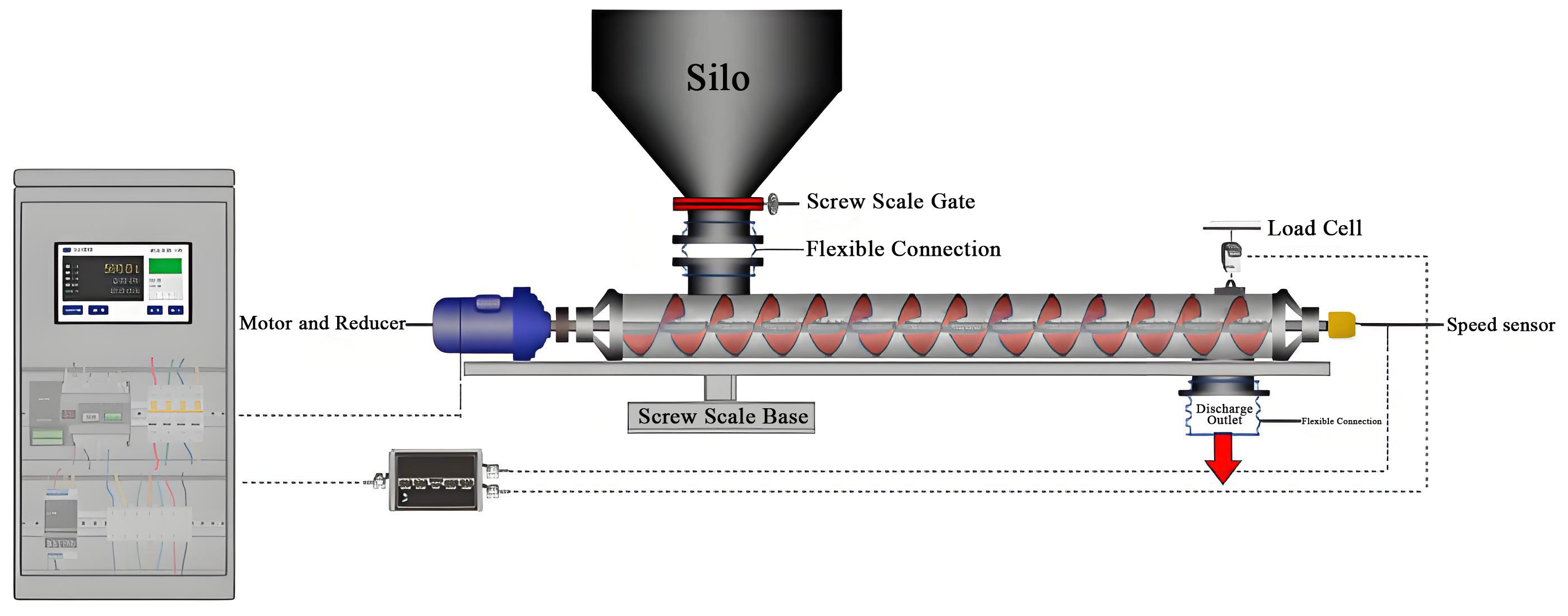

Single tube spiral measuring scale

The single tube spiral weighing feeder is an automated industrial equipment that performs real-time control and dynamic measurement of various powdered materials.

Product Overview

The single tube spiral weighing feeder is an automated industrial equipment that performs real-time control and dynamic measurement of various powdered materials. It has a small volume and can be uniformly transported and measured in a single tube, making it suitable for places with limited working environments. It not only saves space and costs, but also saves time to a certain extent. Suitable for conveying various materials such as coal powder, flour, grains, fertilizers, etc., widely used in many industries such as agriculture, environmental protection, and food.

Refined and efficient spiral

Adopting a single spiral dual function design, the measurement and feeding are completed synchronously, simplifying the structure and saving space. The precision manufacturing process ensures long-term operation without deformation, the sealing structure prevents material leakage, and the transportation is convenient and cost-effective, suitable for the compact production line needs of multiple industries.

Intelligent steady current control

Based on advanced steady flow technology, material transportation is uniform without arching, completely eliminating the risk of material blockage. By combining digital sensors with automatic range calibration, the feeding speed can be dynamically adjusted to ensure long-term stable accuracy of ≤ 1% and improve production continuity.

Convenient intelligent control operation and maintenance

The operation interface is intuitive and supports manual input of parameters, making daily maintenance simple. Integrated zero point automatic tracking function, real-time protection of weighing data; The RS-485 communication interface supports centralized control by industrial control computers, enabling remote monitoring and data tracing, reducing operational complexity.

Working Principle

Double tube constant speed weighing

Under the dual tube structure, the measuring cutter operates at a constant speed (the speed signal is the design value), and three tension sensors collect the cutter load in real time, outputting a voltage signal proportional to the weight to the controller. The controller collaborates with the preset speed signal to calculate the instantaneous flow rate and cumulative weight, ensuring stable measurement.

PID dynamic speed regulation

-

The controller compares the actual flow signal with the set value in real time, dynamically adjusts the output of the frequency converter through PID algorithm, and controls the speed of the feeding cutter. When the flow rate is too high, reduce the speed, and when it is too low, increase the speed, forming a closed-loop feedback to achieve precise quantitative feeding.

Signal collaborative computation

The weight signal output by the tension sensor and the cutter speed signal are co operated in the controller to directly generate instantaneous flow rate and cumulative weight. In dual tube design, the speed signal is fixed to the design value of the cutter, simplifying the calculation logic and improving the system response speed and accuracy.

Structural Composition

Project Case

Guonuo weighing equipment has been successfully applied to multiple domestic and foreign enterprises and has gained widespread recognition

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Scale Project

Based on the site conditions, an ICS-17A belt scale frame was configured, which is a four-idler double-lever type frame with high stability. The sensors are built-in and less prone to damage, effectively mitigating the impact of belt misalig

Fengning Jianyu Iron Mine ICS-17A Belt Weigher Project

The ICS-17A belt weigher adopts a four-idler double-lever scale frame, ensuring high stability and good resistance to eccentric loading.

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Weigher Project

The measurement accuracy of the explosion-proof belt weigher met production requirements, and data could be viewed remotely. Production reports facilitated statistical analysis and management.

Hubei Jingshan Chutian Barium Salt Feeder Project

The feeder's metering and feeding accuracy fully met production requirements and remained stable during prolonged continuous production.

Production Process

Guonuo Technology adopts internationally leading production processes and equipment to ensure stable and reliable quality

Single tube integration

Single tube achieves synchronous metering and feeding, with a compact structure. Precision manufacturing ensures no deformation, and the sealing design prevents leakage.

Data resilience and intelligent control

Power outage protection enables data continuation and remote query enhances management. Large capacity storage supports historical traceability.

Digital sensing anti-interference

The digital sensor automatically calibrates to reduce errors, and IP65 protection ensures stable operation under harsh working conditions.

Durable speed measurement transmission

The brushless pulse generator is maintenance free, and the soft connection technology buffers vibration. The cast aluminum casing is suitable for outdoor environments.

Recommended similar products

Explore other high-quality products from Guonuo Technology to meet your diverse needs

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Scale Project

Based on the site conditions, an ICS-17A belt scale frame was configured, which is a four-idler double-lever type frame with high stability. The sensors are built-in and less prone to damage, effectively mitigating the impact of belt misalig

What are the characteristics of automatic quantitative feeders that align with industrial mass production?

With core advantages such as high precision, high automation, and easy maintenance, automatic quantitative feeders have become indispensable key equipment in modern industrial mass production.

Technical Advantages of Guonuo Technology's Mine Explosion-Proof Electronic Belt Scale

Guonuo Technology, as a manufacturer of mine explosion-proof electrical equipment and industrial weighing and metering devices, leverages its extensive experience, technical prowess, and meticulous attention to detail to introduce a mine exp

Sustainable Development Commitment

Guonuo Technology integrates the concept of sustainable development into the weighing industry, committed to balancing resource development and environmental protection

Environmental protection

- Invest 200 million yuan to build a mine water treatment system, with a water recycling utilization rate of 95%

- Adopting a closed coal transportation system to reduce dust emissions by over 80%

- Implementing the mine land reclamation plan, 1200 acres of vegetation have been restored

social responsibility

- Provide over 500 job opportunities for the surrounding communities of the mining area

- Invest in the construction of 3 Hope Primary Schools and 2 Community Medical Centers

- Annual investment of 10 million yuan for community development and poverty alleviation projects

Future goals

- Reduce carbon emissions intensity in production processes by 20% by 2030

- Invest 500 million yuan to develop low-carbon coal washing technology and clean utilization technology

- Realize 100% land reclamation and ecological restoration of mines by 2030

consulting product

Whether you need to know product details, obtain quotes, or explore long-term cooperation, our professional team will provide you with high-quality service.