Quantitative weighing feeder

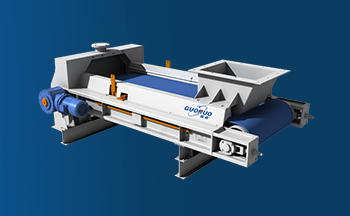

Guonuo Quantitative Weighing Feeder is an automated measuring equipment designed for continuous weighing of bulk materials

Product Overview

Guonuo Quantitative Weighing Feeder is an automated metering device designed for continuous weighing of bulk materials. It is a continuous weighing and feeding equipment developed through digestion, absorption and improvement based on advanced technologies at home and abroad. Featuring stable and reliable operation, it can achieve accurate quantitative feeding. Not only can it help users reduce material waste, but also effectively improve the metering efficiency of product production. Therefore, it is widely used in industries such as coal power, cement, chemical engineering and metallurgy.

Smart Core

The core is equipped with independently developed intelligent instruments, which use high-speed computing power and intelligent algorithms to achieve zero point automatic tracking and self diagnosis of operational faults. This endows the equipment with the ability to resist interference and adapt to harsh working conditions, ensuring continuous and stable accurate measurement.

Precision Craftsmanship

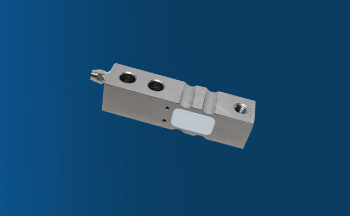

We adhere to a global optimization strategy for key components, with sensors and electronic control elements all sourced from top international brands. This strategy ensures exceptional durability and reliability from the hardware source, laying a solid foundation for the equipment's long service life and low failure rate.

Accurate performance

A closed-loop accuracy assurance system has been constructed through the synergistic effect of multiple compensation techniques and high-resolution speed measurement. Combined with strict calibration before leaving the factory, it ensures that the equipment can resist various types of error interference in practical applications, achieving the unity of high precision and high stability.

Working Principle

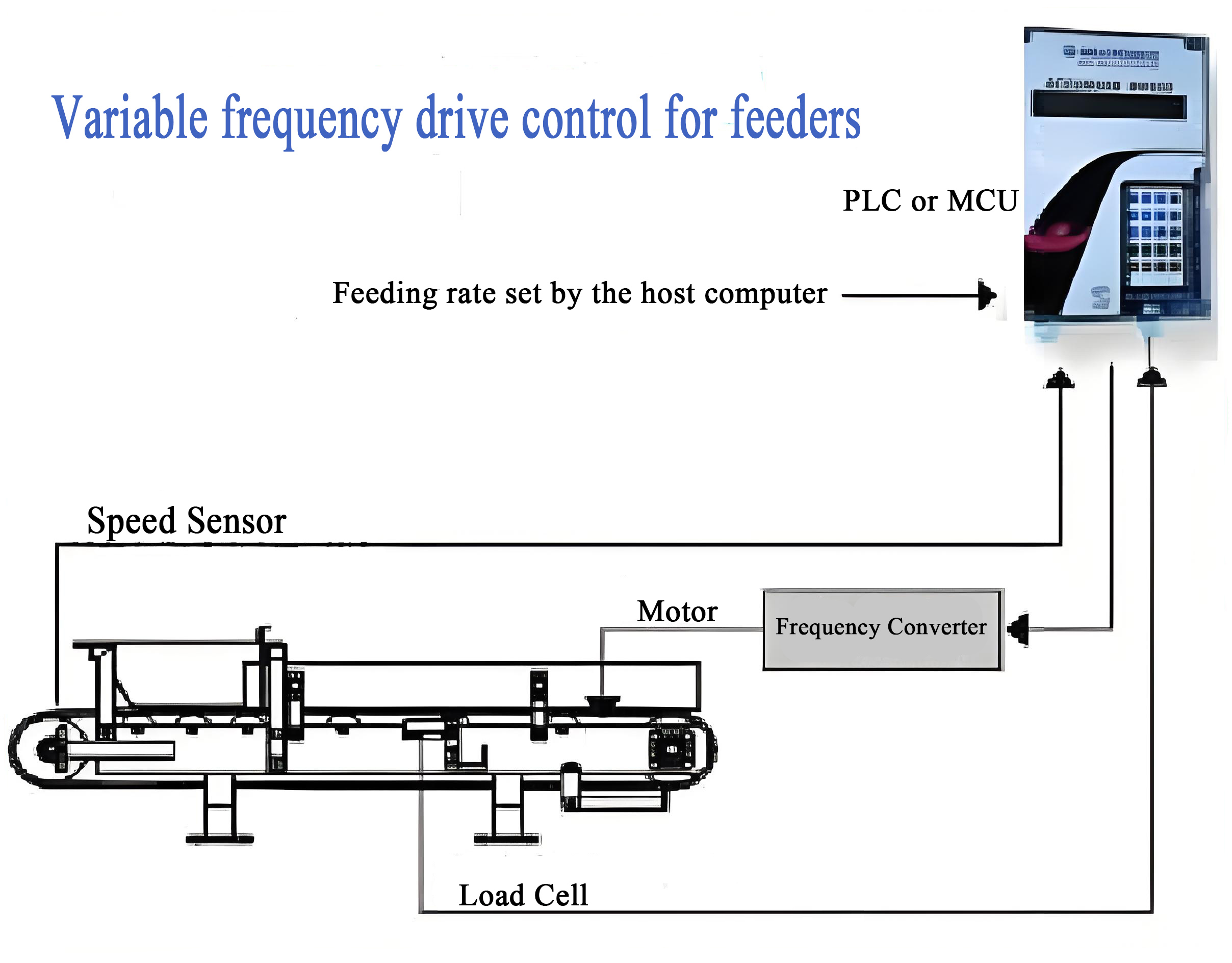

Control principle

The system continuously monitors the actual feeding quantity and compares it with the preset target. When a deviation occurs, it immediately adjusts the speed of the belt motor: increasing the speed if the quantity is lower than the target, and decreasing the speed if it is higher. This cycle forms a dynamic self-optimizing closed loop to ensure the stability of the feeding quantity.

Continuous weighing

-

The weighing sensor detects the weight of materials per unit length, and the speed measuring device monitors the belt speed. The system calculates the instantaneous and cumulative flow by multiplying the load and speed, ensuring the uninterrupted operation of the production process.

Set Tracking

The system takes the set feeding quantity as the reference. Regardless of fluctuations in external conditions, it actively tracks the target by adjusting the belt speed. The controller compensates for disturbances like "autopilot," ensuring the stability of product quality.

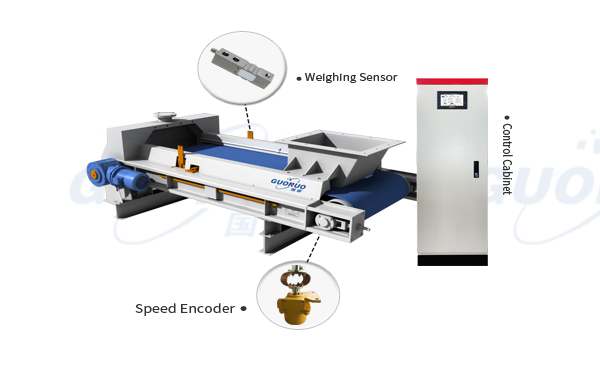

Structural Composition

Project Case

Guonuo weighing equipment has been successfully applied to multiple domestic and foreign enterprises and has gained widespread recognition

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Scale Project

Based on the site conditions, an ICS-17A belt scale frame was configured, which is a four-idler double-lever type frame with high stability. The sensors are built-in and less prone to damage, effectively mitigating the impact of belt misalig

Fengning Jianyu Iron Mine ICS-17A Belt Weigher Project

The ICS-17A belt weigher adopts a four-idler double-lever scale frame, ensuring high stability and good resistance to eccentric loading.

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Weigher Project

The measurement accuracy of the explosion-proof belt weigher met production requirements, and data could be viewed remotely. Production reports facilitated statistical analysis and management.

Hubei Jingshan Chutian Barium Salt Feeder Project

The feeder's metering and feeding accuracy fully met production requirements and remained stable during prolonged continuous production.

Production Process

Guonuo Technology adopts internationally leading production processes and equipment to ensure stable and reliable quality

Modular process

It adopts a modular fully suspended structure, which eliminates trunnion fulcrums and deformation, ensures accurate force transmission, and simultaneously improves stability and maintenance convenience.

Intelligent Control Technology

It is equipped with power-off protection and seamless data transmission functions, supports remote real-time query and large-capacity historical data storage, and enhances the continuity and intelligence level of management.

Digital technology

Digital sensors are used to achieve anti-interference and rapid response; combined with automatic calibration technology, it reduces errors. The IP65 protection level ensures reliable operation in harsh environments.

Durable craftsmanship

Brushless pulse generators are adopted to realize maintenance-free operation; flexible connection technology is used to buffer vibration, and aluminum alloy cast shells provide outdoor protection—all of which jointly improve the overall service life of the equipment.

Recommended similar products

Explore other high-quality products from Guonuo Technology to meet your diverse needs

Shanxi Honghaifu Mining Equipment Explosion-Proof Belt Scale Project

Based on the site conditions, an ICS-17A belt scale frame was configured, which is a four-idler double-lever type frame with high stability. The sensors are built-in and less prone to damage, effectively mitigating the impact of belt misalig

What are the characteristics of automatic quantitative feeders that align with industrial mass production?

With core advantages such as high precision, high automation, and easy maintenance, automatic quantitative feeders have become indispensable key equipment in modern industrial mass production.

Technical Advantages of Guonuo Technology's Mine Explosion-Proof Electronic Belt Scale

Guonuo Technology, as a manufacturer of mine explosion-proof electrical equipment and industrial weighing and metering devices, leverages its extensive experience, technical prowess, and meticulous attention to detail to introduce a mine exp

Sustainable Development Commitment

Guonuo Technology integrates the concept of sustainable development into the weighing industry, committed to balancing resource development and environmental protection

Environmental protection

- Invest 200 million yuan to build a mine water treatment system, with a water recycling utilization rate of 95%

- Adopting a closed coal transportation system to reduce dust emissions by over 80%

- Implementing the mine land reclamation plan, 1200 acres of vegetation have been restored

social responsibility

- Provide over 500 job opportunities for the surrounding communities of the mining area

- Invest in the construction of 3 Hope Primary Schools and 2 Community Medical Centers

- Annual investment of 10 million yuan for community development and poverty alleviation projects

Future goals

- Reduce carbon emissions intensity in production processes by 20% by 2030

- Invest 500 million yuan to develop low-carbon coal washing technology and clean utilization technology

- Realize 100% land reclamation and ecological restoration of mines by 2030

consulting product

Whether you need to know product details, obtain quotes, or explore long-term cooperation, our professional team will provide you with high-quality service.